Sold!Buy one like this

I want to sell a machine like this

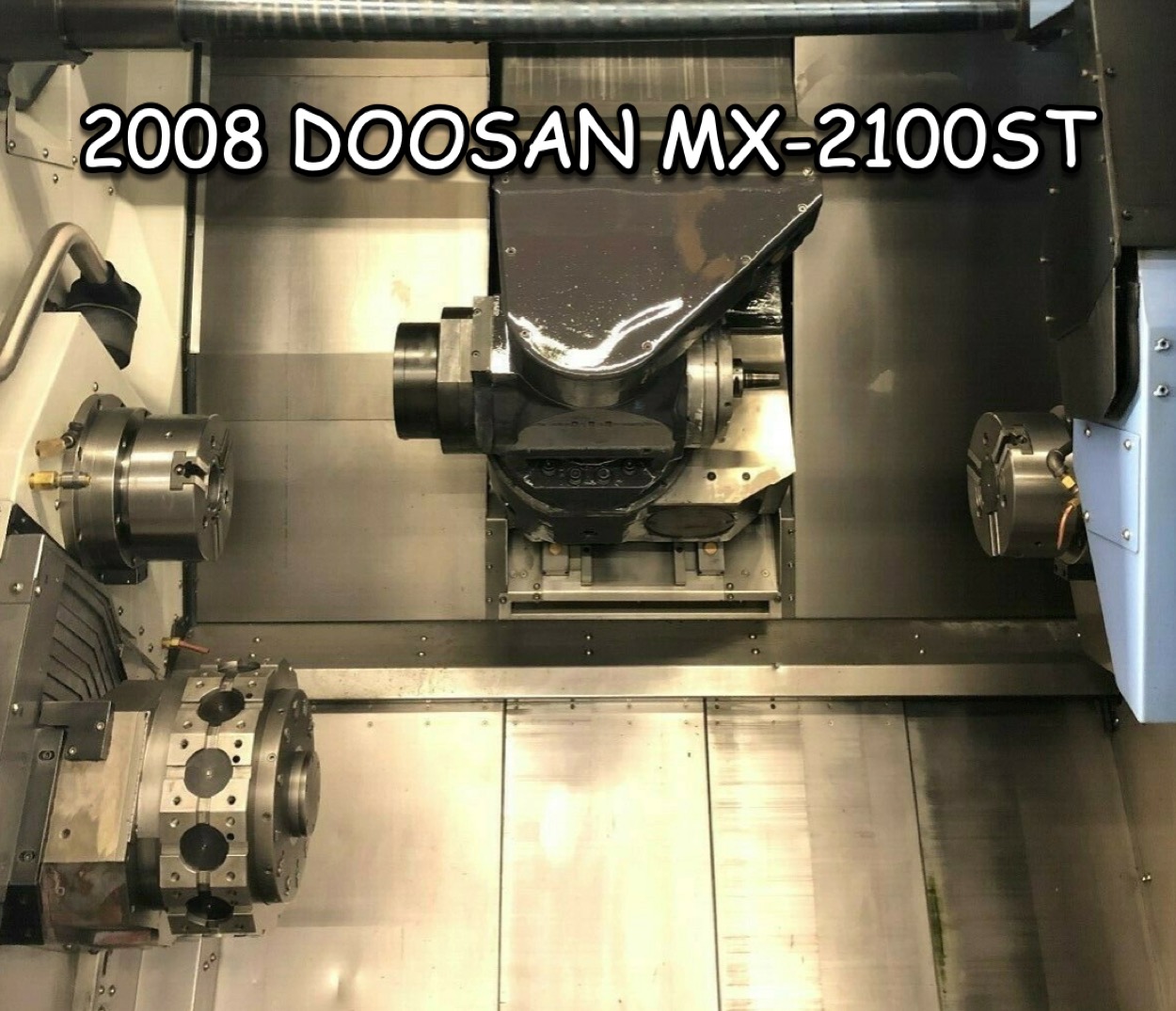

- CNC Machine

- Daewoo Doosan

- MX2100ST

- Lathe - CNC

- 2008

- Spindle Size: 2.65"

- B Axis:

- C Axis:

- Y Axis:

- Dual Spindles:

- Sub Spindle:

- Live Tooling:

Specifications

Doosan MX-2100ST Specifications:Capacity:

Max Turning Diameter Upper Turret : 21.25″

Max Turning Diameter Lower Turret : 11.89″

Max Swing Upper Turret : 29.5″

Max Swing with Y Axis : 19.70″

Max Swing over Cross Slide : 23.6″

Max Turning Length: 40.15″

Max Bar Capacity Main Spindle : 2.625″

Max Bar Capacity Sub Spindle : 2.55″

Max Weight on Main & Sub Spindle : 1322 lbs

Max Distance Between Main & Sub Spindle: 52.50″

Travels:

X1 Axis Travel Upper : 22.24″

X2 Axis Travel Lower : 7.36″

Z1 Axis Travel Upper : 41.3″

Z2 Axis Travel Lower : 41.3″

Y Axis Travel: 6.7″

W Axis Travel: 41.34″ ( Sub Spindle )

C Axis: 360° (0.001°) Both Spindle

B Axis Travel: 240°

Feedrate:

Rapid Traverse X Axis: 1417 IPM

Rapid Traverse Z Axis: 1417 IPM

Rapid Traverse Y Axis: 1351 IPM

Rapid Traverse B Axis: 1181 IPM

Spindle:

Main Spindle Bore: 2.99″

Sub Spindle Bore: 2.99″

Main Spindle Nose: A2-6

Sub Spindle Nose: A2-6

Main Spindle Speed: 35-5000 RPM

Sub Spindle Speed: 35-5000 RPM

Main Spindle Power: 22 kw

Sub Spindle Power: 22 kw

Milling Head:

Single Station Pendulum Head with 40 ATC

Tool Type: CAPTO-C6, 40 Taper

Spindle Speed: 15-12000 RPM

Spindle Motor: 18.5 kw

Spindle 5° Index Time: 0.5 Sec

Lower Turret:

Capacity: 12 Live Stations

Tool Holder Type: BMT-55P

Turret Index Time: 0.2Second

OD Tool Size: 1.00″

ID Tool Size : 1.50″

Live Tool Speed: 5000 RPM

General:

Power: 87 kva, 220v / 3-Phase

Air Required: 71 PSI

Overall Dimensions: 192″ x 99″ x 110″ High

Overall Dimensions: 210″ x 99″ x 110″ High with Chip Conveyor

Weight: 26,500 lbs

Notes

Doosan MX-2100ST Equipped With:

Fanuc 31iA CNC Control

12000 RPM Pendulum Milling Head

Powerful (22kw) 30 HP high-torque integral spindle motors

High speed 5,000 RPM spindles

Servo driven 40 station ATC with 1.8 sec tool to tool time

Servo Controlled Full C-Axis on Both Spindles

12 Station lower turret with Live tool capability

Y Axis Capability

PCMCIA Card Slot

Tool monitoring system – wear and breakage detection

Automated Parts Unloading system

8″ Big Bore Chuck on Main Spindle

8″ Chuck on Sub Spindle

Rigid Tapping on Both Spindles

Foot Operated Control for Chuck

High Pressure Coolant System

Chip Conveyor

Inbuilt Transformer

Chiller Unit

Comes with Tools, Chip Conveyor, Books & Manuals.